Clamps, those seemingly simple tools, are indispensable in a wide range of applications, from woodworking and metalworking to construction and DIY projects. They come in various shapes and sizes, each designed to provide secure holding and stability for different tasks. Whether you’re a seasoned craftsman or a novice DIY enthusiast, understanding the different types of clamps and their proper usage is crucial for achieving accurate and efficient results.

From the versatile C-clamps to the powerful bar clamps and the precise machinists’ vises, each type of clamp offers unique advantages and is tailored to specific applications. By selecting the right clamp for the job, you can ensure that your workpieces are held securely in place, allowing you to focus on the task at hand without worry.

In this comprehensive guide, we will explore the diverse world of clamps, delving into their various types, their applications, and essential safety considerations. We will also provide practical tips on how to use clamps effectively to maximize their potential and achieve optimal results.

Understanding the Basics of Clamps

At their core, clamps are mechanical devices that apply pressure to hold objects together. They typically consist of two jaws that can be tightened or loosened using a screw, lever, or other mechanism. The clamping force exerted by the jaws varies depending on the type of clamp and the specific application.

Common Types of Clamps

C-Clamps:

Versatile and widely used for general-purpose clamping.

Ideal for holding workpieces together while gluing, welding, or drilling.

offered in a range of sizes to suit varying workpiece dimensions.

Bar Clamps:

Used to apply clamping force over longer distances.

Commonly used in woodworking for gluing large panels together.

Often come in sets of two or more to provide additional clamping power.

Spring Clamps:

Quick-release clamps that are easy to use and ideal for temporary holding.

Commonly used in woodworking, metalworking, and assembly tasks.

Available in various sizes and jaw capacities.

F-Clamps:

Similar to C-clamps but with a longer, angled jaw that provides better access to workpieces.

Ideal for clamping irregular shapes and workpieces in tight spaces.

Pipe Clamps:

Specifically designed to clamp pipes and tubing securely in place.

Often used in plumbing, HVAC, and construction.

Bench Vise:

A stationary clamping tool that securely holds workpieces for various operations.

Commonly used in workshops for sawing, drilling, and shaping metal or wood.

Machinist’s Vise:

A precision clamping tool used in metalworking and machining.

Provides accurate alignment and secure holding for precise operations.

How to Use Clamps Effectively

Choose the Right Clamp: Select a clamp that is appropriate for the size, shape, and material of the workpieces.

Position the Workpieces: Ensure that the workpieces are properly aligned and positioned before clamping.

Apply Clamping Force: Tighten the clamp gradually to avoid damaging the workpieces.

Monitor Clamping Pressure: Overtightening can lead to workpiece damage or clamp failure.

Release the Clamps: Once the work is complete, release the clamps carefully to avoid damaging the workpiece or the clamp itself.

Safety Considerations

Inspect Clamps Regularly: Check for signs of wear, damage, or loose parts.

Wear Protective Gear: Use safety glasses, gloves, and other protective gear when working with clamps.

Avoid Overloading: Do not exceed the rated capacity of the clamp.

Use Proper Techniques: Follow recommended techniques to prevent accidents.

FAQs

What are clamps, and what are they used for?

Clamps are mechanical devices that secure or hold objects tightly together to prevent movement or separation through the application of inward pressure. They are essential tools in various fields, including woodworking, metalworking, construction, automotive repair, and crafting. In woodworking, for instance, clamps are used to hold pieces of wood together while glue sets, ensuring proper alignment and a strong bond. In metalworking, they are crucial for securing workpieces during welding or cutting processes. Clamps come in many styles and sizes, each tailored to specific tasks, making them versatile tools for both professional and amateur projects.

What is the best clamp to use for my project?

Selecting the right clamp depends on the size and type of materials you’re working with, the pressure required, and the specific task. For instance:

For woodworking, a bar clamp may be ideal for gluing large panels.

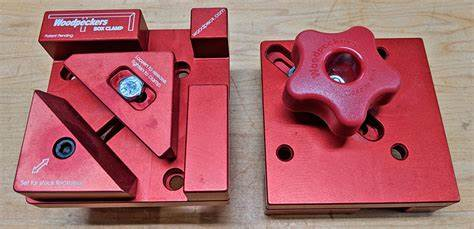

If you need to secure two pieces at a right angle, a corner clamp would be more suitable.

For quick tasks or lightweight materials, spring clamps are efficient.

What is the maximum clamping force for different clamps?

The clamping force varies by type and size. For example:

C-Clamps can exert several tons of pressure, depending on their size.

Bar Clamps typically range from 300 to 1,000 pounds of clamping force.

Spring Clamps exert less force, usually suitable for lighter tasks (around 10-50 pounds).

Always check the manufacturer’s specifications to ensure you’re aware of the limits for safe use.

How do I properly use a clamp?

To use a clamp effectively:

Position the clamp jaws on the materials to be joined, ensuring they are aligned.

Gradually tighten the clamp, applying even pressure. Avoid overtightening, which can damage the material.

For temporary holds, consider using a light-duty clamp, while heavy-duty clamps are best for permanent assemblies.

Always check the alignment and adjust as necessary before fully tightening.

Can clamps damage my materials?

Yes, clamps can potentially damage materials if used improperly. Overtightening can cause dents, splintering, or even breakage, especially in softer woods. To prevent this, use:

Clamp pads or protective sleeves to distribute pressure evenly.

Light pressure initially to check alignment before tightening further.

The right type of clamp for the material and task.

How should I maintain my clamps?

Proper maintenance ensures longevity and functionality:

Regularly clean clamps to remove dust and debris, especially in moving parts.

Lubricate threaded parts with a light oil to keep them moving smoothly.

Inspect for wear or damage, especially on jaws and screws, and replace if necessary.

Store clamps in a dry place to prevent rust and corrosion.

In summary

clamps are indispensable tools that play a vital role in various industries and DIY projects. From woodworking and metalworking to plumbing and construction, clamps provide the necessary stability, precision, and efficiency to complete tasks effectively. By understanding the different types of clamps, their applications, and proper usage techniques, you can harness their power to achieve professional-quality results. Remember to prioritize safety, inspect your clamps regularly, and use them responsibly to ensure a positive and productive experience.

To read more, Click here

Leave a Reply